I have worked on many kinds of events—from staging, curation, signage design, stage design, booth design… for that matter, as a speaker, a track chair, and a host—but for this occasion, I'm focused on events where my primary responsibility was creating design elements (media related events can be found in the PR section).

For Chevron, I was brought in as a designer for a wall size touchscreen. The technology vendor had a rear-projection setup with four light sources that incorporated a low-profile perimeter frame that used an infrared beam matrix & sensor system, just millimeters above the display surface. When the user's hand (or fingertip) broke the beam, it would calculate the X & Y axis, and composite it to the displays behind.

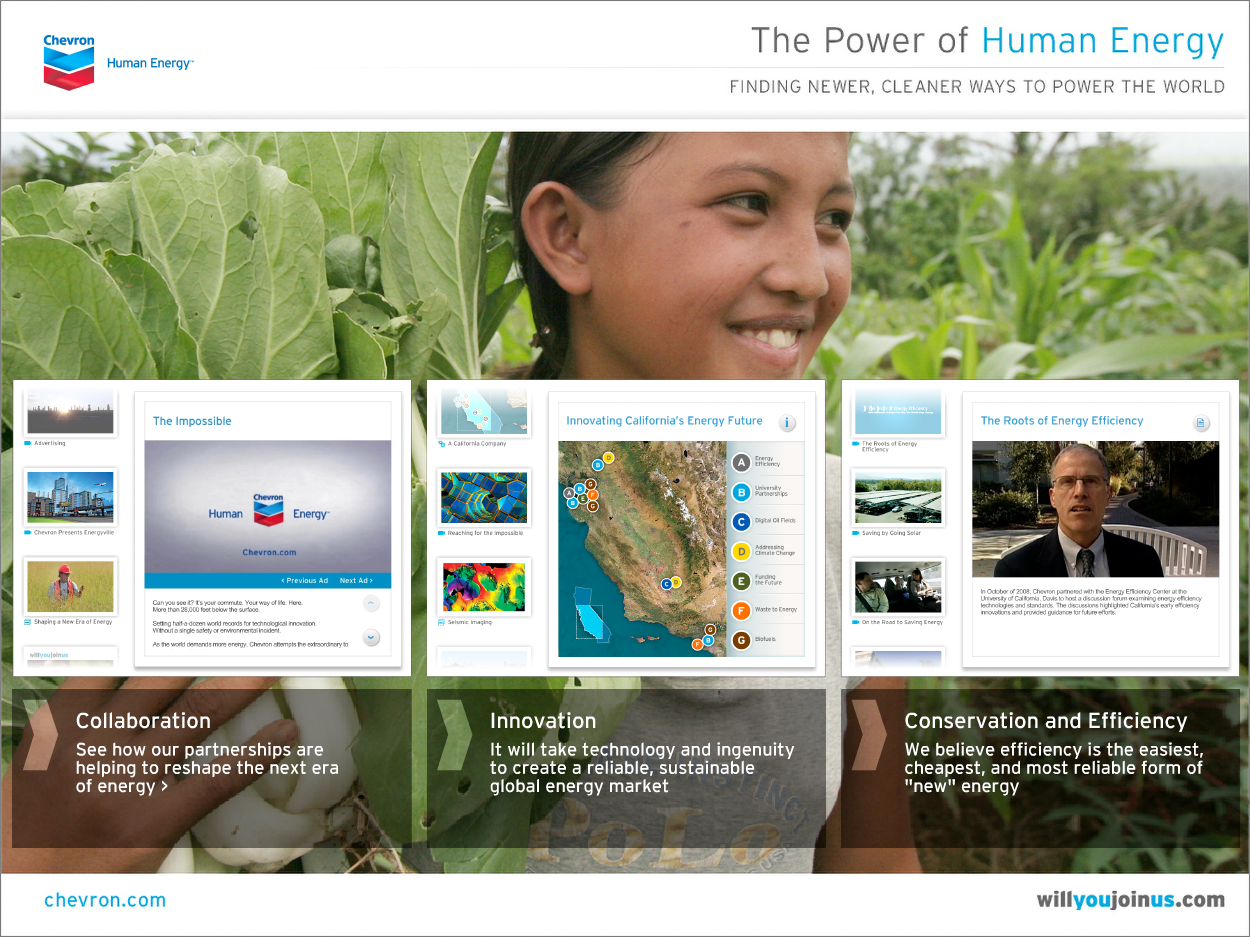

McGarryBowen had the account, and their digital group had already sold in the three module concept. The Chevron style guide required tight adherence; the wireframes were complete, and signed off on. Brought in as a contractor, some of the interactive components—like the center module California energy map shown below—did afford me a few opportunities to be creative, but it was mostly a massive production-artist job (all me).

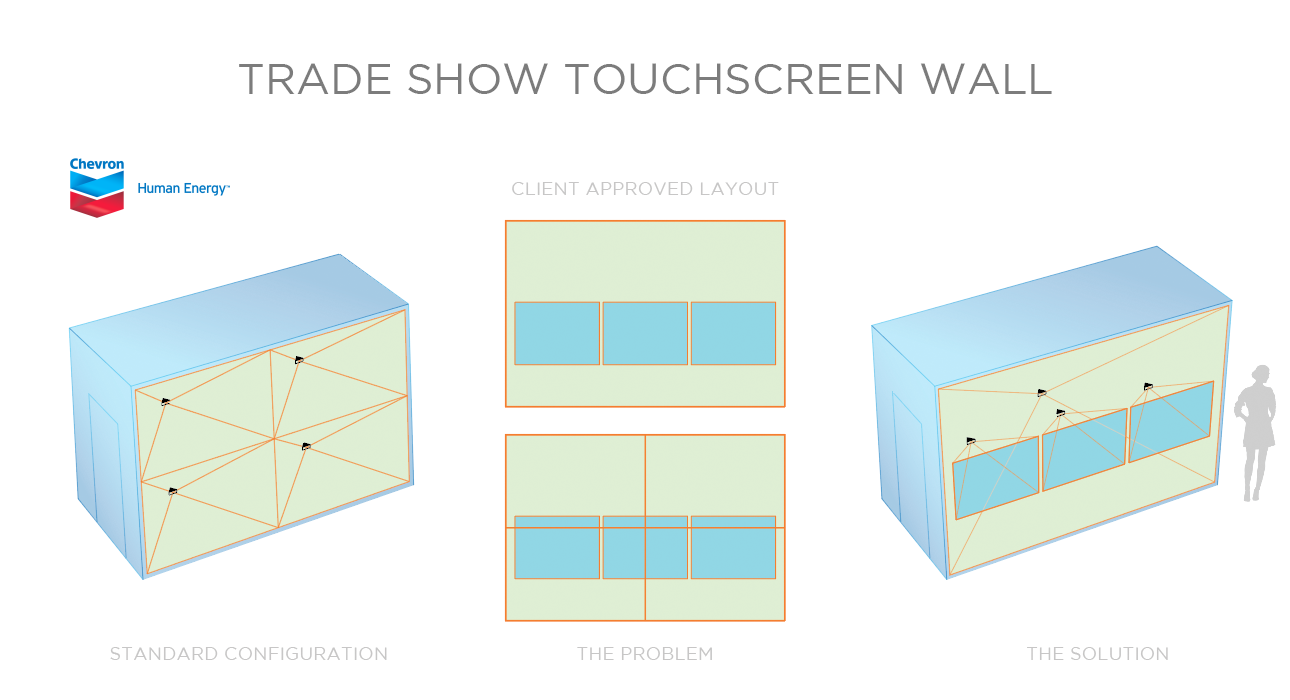

I buried the lede … On this project, my most significant contribution was in fact a technical one: the technology vendor's display system was placed into a projection room behind the display, and consisted of a grid of four panels, from four projectors (see illustration above). The small overlap of each projector left a visible seam that was not in any way aligned with the approved three panel layout. There was no time to go back to wireframes and redesign the whole project. Chevron was an important client, and let it be known that the visible seams were not acceptable. The vendor explained to us that most clients used these massive rear-projection setups for oversized motion graphics, where the seams were much less visible. But because our design was mostly static and had a competing grid, it drew tremendous attention to the problem.

It was a crisis.

I inquired with the vendor if the projectors' display areas were fixed in size?

Answer: No.

I came up with the idea of placing one projector behind each of the three modules, and a fourth projector for the whole background, with the front projectors projecting up from below. It took a couple of days for the vendor to re-rig the projection system, but it worked.

There is a safety area where the larger projection maintains a white border on the inside of the "blank" module box, and the projectors for each module have a large white border. If the "seam" is in any way out of alignment, it just projects white on white, and is not visible at all.

Chevron toured this installation to tradeshows around the country (around the world?) for a couple of years.

Play video of left module: